Star Rapid InjectionMolding Service FAQ

These are the common injection moldingquestions at Xinjuexin.

Injection moulding is a manufacturing process that allows for parts to be produced in large volumes. It works by injecting molten materials into a mould/mold. It is typically used as a mass production process to manufacture thousands of identical items. Injection moulding materials include metals, glasses, elastomers and confections, although it is most commonly used with thermoplastic and thermosetting polymers. Injection moulding consists of the high pressure injection of the raw material into a mould, which shapes the polymer into the desired form. Moulds can be of a single cavity or multiple cavities. In multiple cavity moulds, each cavity can be identical and form the same parts or can be unique and form multiple different geometries during a single cycle. Moulds are generally made from tool steels, but stainless steels and aluminium moulds are suitable for certain applications. Aluminium moulds are typically ill-suited for high volume production or parts with narrow dimensional tolerances, as they have inferior mechanical properties and are more prone to wear, damage, and deformation during the injection and clamping cycles; however, aluminium moulds are cost-effective in low-volume applications, as mould fabrication costs and time are considerably reduced. Many steel moulds are designed to process well over a million parts during their lifetime and can cost hundreds of thousands of dollars to fabricate.

When thermoplastics are moulded, typically pelletised raw material is fed through a hopper into a heated barrel with a reciprocating screw. Upon entrance to the barrel, the temperature increases and the Van der Waals forces that resist relative flow of individual chains are weakened as a result of increased space between molecules at higher thermal energy states. This process reduces its viscosity, which enables the polymer to flow with the driving force of the injection unit. The screw delivers the raw material forward, mixes and homogenises the thermal and viscous distributions of the polymer, and reduces the required heating time by mechanically shearing the material and adding a significant amount of frictional heating to the polymer. The material feeds forward through a check valve and collects at the front of the screw into a volume known as a shot. A shot is the volume of material that is used to fill the mould cavity, compensate for shrinkage, and provide a cushion (approximately 10% of the total shot volume, which remains in the barrel and prevents the screw from bottoming out) to transfer pressure from the screw to the mould cavity. When enough material has gathered, the material is forced at high pressure and velocity into the part forming cavity. The exact amount of shrinkage is a function of the resin being used, and can be relatively predictable. To prevent spikes in pressure, the process normally uses a transfer position corresponding to a 95–98% full cavity where the screw shifts from a constant velocity to a constant pressure control. Often injection times are well under 1 second. Once the screw reaches the transfer position the packing pressure is applied, which completes mould filling and compensates for thermal shrinkage, which is quite high for thermoplastics relative to many other materials. The packing pressure is applied until the gate (cavity entrance) solidifies. Due to its small size, the gate is normally the first place to solidify through its entire thickness. Once the gate solidifies, no more material can enter the cavity; accordingly, the screw reciprocates and acquires material for the next cycle while the material within the mould cools so that it can be ejected and be dimensionally stable. This cooling duration is dramatically reduced by the use of cooling lines circulating water or oil from an external temperature controller. Once the required temperature has been achieved, the mould opens and an array of pins, sleeves, strippers, etc. are driven forward to demould the article. Then, the mould closes and the process is repeated.

Compression molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured; this process is known as compression molding method and in case of rubber it is also known as ‘Vulcanisation’.The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms.

Compression molding is a forming process in which a plastic material is placed directly into a heated metal mold then is softened by the heat and therefore forced to conform to the shape of the mold, as the mold closes. Once molding is completed excess Flash may be removed. Typically, compression molding machines open along a vertical axis.

For prototype samples or small trial order, there are few processes as below:

(1) By 3D printing, there are some popular process, such as SLA, FDM, SLS, FFF. Attached please find the material features of 3D printing process for your reference.

A. For SLA, the precision is high, but the material is resin, which is brittle and easy to deform. It is not suitable for the practical application of the product. It is suitable for the parts with complex shape and structure, which do not need too much support. It is suitable for the first stage to confirm the design before mould making;

B. For FDM, it’s suitable for sculpture or some functional parts with a precision of about 0.1mm, which can be used as parts for the practical products. The materials are generally thermoplastic materials, such as ABS, PC, POM, Nylon, etc;

C. For SLS, it’s suitable for complex design and do not need support products. The price is high, and the parts will be deformed in the case of sealing. It is suitable for the first stage to confirm the design before mould making. Material: Nylon powder.

D. For FFF, it’s suitable for printing large size and heavy products. For example, bar counter, sculpture, big pendant, car inside and outside ornaments, models etc. It can replace the technology of wood mold. For the deformation, SLA resin is the largest, then SLS nylon, and finally FFF high performance materials. So all the processes need to match your requirements, such as the prototypes sample stage or the actual functional parts? What is the operation temperature? What is the surface roughness? Is it used in closed conditions? Is there a coating requirement? Life cycle requirements etc… The more requirements you give, the more accurate the process and materials we recommend.

(2) By vacuum casting process. The material is more stronger than the SLA process. This process is suitable for the first stage to confirm the design at begining. And suitable for the first small trial order.

(3) By CNC machining, the material can be same as the future mass production, which can save the mould cost. Suitable for the small trial order. But for this process, it has struction limited. Not all struction can be machined out.

(4) By a sample mold with 1 cavity. In that case, the material from the samples will be exactly same as the future mass production.

(5) If the design is confirmed, we can proceed the mould making, and will provide some samples for test after mould ready, before mass production. We can provide all above points prototyping/samples services, you can choose the suitable one for each project and stages.

This flowchart shows our workflow. Once you confirm the order, we will sent you the DFM (design for manufacturability) analysis.

Design for manufacturability (DFM) is the general engineering practice of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology. DFM describes the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. DFM will allow potential problems to be fixed in the design phase which is the least expensive place to address them. Other factors may affect the manufacturability such as the type of raw material, the form of the raw material, dimensional tolerances, and secondary processing such as finishing.

We’ll start to design the mould drawing and mould making after the DFM report approved by customer. Once the mould making is finished, we’ll make several pieces of pre-production samples for test, if the dimensions are correct, then we will send the samples to customers for final confirmation. If the test failed, we will modify the mould or adjust the molding parameter to make new samples, and test it again. Once the samples are approval by customers, we will purchase the raw material and making quality inspection. Then mixing material, molding and trimming, we will make many times of inspection during the production. Finally we will arrange the assembly and packing. After whole order is ready, we will send the packing list to customer to arrange the shipment.

100% inspection for order,we seriously take care of the quality control from IQC to OQC, throughout each step of the production. Let us show you our quality control:

For raw materials, we’ll do the IQC in time. All materials are procured only from the verified suppliers, who have implemented and maintain certified quality management systems in their plants. With full certificates, such as RoHs, Reach, MSDS, FDA, LFGB, UL, EN549, BPA free, EN71, and so on;

For pre- production samples, we’ll provide several pieces tp our clients for assembly and function testing. We will seal the samples in time once they’re approval.

For Bulk Production, we’ll do the IPQCS & PQC (Multiple Sampling Inspection) during production and we’ll do the FQC (Sampling Inspection) after deburr or breaking sharp edges. In order to timely find problems, solve problems, reduce defective products, reduce manufacturing costs.

After packing and assembling, we’ll do the OQC (Sampling Inspection) to make sure the final goods are qualified.

A. If you have sample in hand, please deliver it to us, we can calculate the cost according to your sample, and scan the drawing out accordingly.

B. If you don’t have drawing, but have an idea, please advise your idea in details, we can help you to design out the drawing according to your idea.

If you can dream it, we can build it!

- The number of cavities incorporated into a mould directly correlate in moulding costs. Fewer cavities require far less tooling work, so limiting the number of cavities lowers initial manufacturing costs to build an injection mould.

- As the number of cavities play a vital role in moulding costs, so does the complexity of the part’s design. Complexity can be incorporated into many factors such as surface finishing, tolerance requirements, internal or external threads, fine detailing or the number of undercuts that may be incorporated.

- Further details, such as undercuts, or any feature that needs additional tooling, increases mould cost. Surface finish of the core and cavity of moulds further influences cost.

- Rubber injection moulding process produces a high yield of durable products, making it the most efficient and cost-effective method of moulding. Consistent vulcanisation processes involving precise temperature control significantly reduces all waste material.

- The quality of tooling is very very important, it affects the quality of final product. So we’d like to pay more attention on the quality of tooling. Some of our customers delivered us the samples from other suppliers because of their poor quality, and ask us to make new mould and mass production accordingly because of our top quality.

- You only need to pay the mould charge for the first order, you don’t need to pay for the mould cost again for future repeat orders.

Work with Xinjuexin, your money is in safe and your business is in safe. Because Xinjuexin only produce high quality products, we are one of the few companies who can offer :

1: Non-Disclosure Agreement

2: Refund agreement

3: Quality assurance agreement

4: Delivery time agreement

We can not say we are the best in China, but we are the most reliable one, and we never stop chasing the best.

Yes, we support customization color. For plastic injection molding parts and silicone molded parts, all colors can be molded out directly except metallic colors, gold and silver colors. If you need the metallic colors, gold and silver color, you can choose to paint after molded to match the colors. For full PANTONE colourchart, please download here . And you can contact your Account Manager or [email protected] to request the PANTONE colourchart directly. If there is nothing in it you want, please provide your preferred pantone number, or provide a color sample, we’ll adjust the color accordingly.

Sink marks are a common phenomenon on injection molded parts. Shrinkage of plastic components is driven by the volumetric change of the material as it cools from the melt state to solid. We want to help product developers mitigate the effects of sink marks by using design best practices.

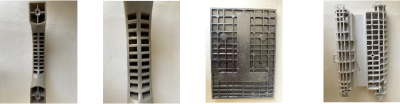

These are our examples.

Adding ribs to mitigate sink risks:

For areas with thicker walls to increase strength, coring and leaving structural ribs can achieve the same effect — preserving structure and strength while reducing the risk of subsidence.